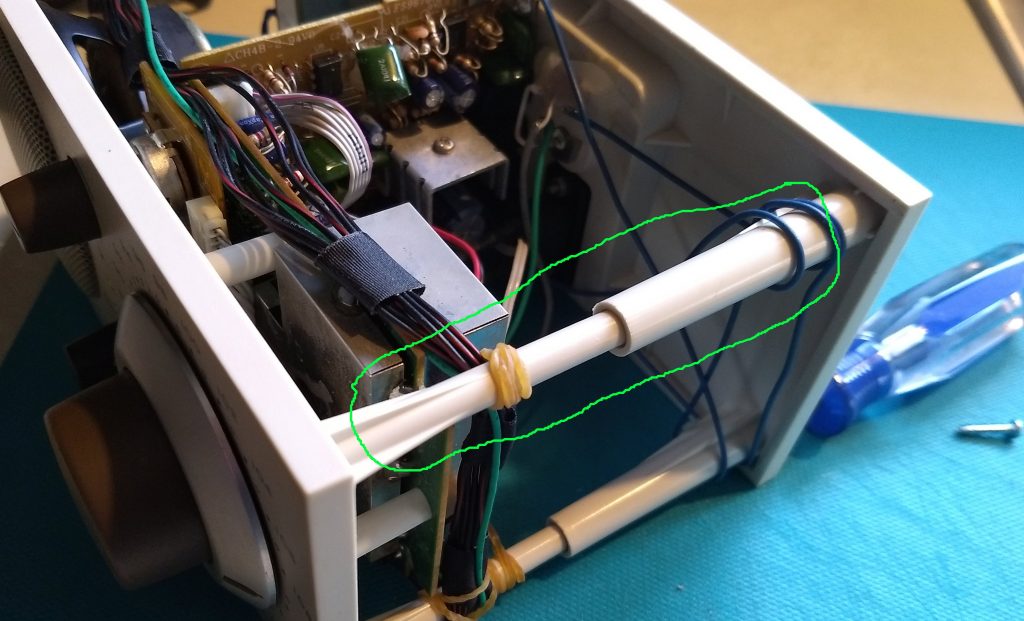

On a Model One/Model Two/Model Three, there are these plastic things that connect the front panel directly to the back panel. (OK, it’s about time for a photo)

The four screws in the 4 corners in back of the radio basically anchor into extensions of the front panel. Sometimes these get stripped or broken if the screws are over-tightened, sometimes it’s the factory’s fault and the boss was not strong enough. Don’t Overtighten! Maybe it’s been tightened by somebody who thought it was a machine screw, when in fact it’s more like a sheet metal screw or a wood screw that bites into the plastic. If they break, usually the front half breaks about halfway back. I’ve seen a Model Two radio fresh out of the box with all 4 bosses broken. Really!

How can I tell it’s broken/stripped? The screw just spins when it should be fully tightened.

Bosses seem to break way more often on Model Two’s than any other radio. We have theories as to why, but it doesn’t really matter because the Model Two is out of production and we just fix ’em, we don’t build them. Model Three’s are a close second in broken bosses.

What we do: Bruce will put a bit of epoxy in there to give the screw something substantial to bite into if it’s stripped, sometimes he’ll put a bit of toothpick or a short piece of pipe cleaner (which holds epoxy really well) to reinforce the boss along with epoxy. Sometimes the Boss breaks apart on the female side (attached to the front panel of the radio, each one is almost 2 inches long) but beyond where the screw bites into it and Bruce will put a length of Brass rod and Epoxy into the void, to give it good strength.

Is this a bad thing? it’s not like the radio will fall apart. Well, if the front and back aren’t tight against the cabinet, you may get an air leak, and that means that the port isn’t doing it’s job properly and the radio will not sound as it is designed to, and sometimes it may rattle. Remember… when the driver (speaker) is making sound, it’s basically a piston moving back and forth in the cabinet which is filled with air, the lower the frequency, the more it moves, and that air in the cabinet is channeled in and out the port (that hole in the bottom or back of the radio) which is specifically sized to reproduce those low frequencies.

Because we’re nice guys we do this Cheap (mostly) for Free!: Sorry, but no longer Free. Bruce might fix one boss for free if he’s in a good mood, more than that $10 flat rate per radio. sometimes this requires we replace the front panel and we charge for that too! It’s a real pain in the ass, If we have the radio open to fix something else, it’s not a big deal to do it for one boss, but the more that are broken the harder it gets exponentially. We have high standards and Bruce doesn’t like radios going out the door unless they sound perfect. Bruce sometimes only notice this when re-assembling the radio and has to put it aside overnight to let the epoxy cure, but that’s the only way to do it right.

Fun Fact: Bruce and I have actually had an argument over what epoxy to use on broken bosses. Bruce no longer insists on repairing them for free Bruce does the work and just complained that he spent $24 on brass rod and epoxy so he decided that a charge was appropriate . Jedi mind control not working on Bruce as well as I had hoped.